What is a Waterproof Rocker Switch and How is it Used?

The Waterproof Rocker Switch is an essential component in many industries. It provides reliable on/off control in various environments. According to a report by Market Research Future, the global market for waterproof switches is expected to grow by 5.4% annually. This growth is driven by demand in automotive, marine, and outdoor equipment sectors.

Waterproof rocker switches are designed to withstand harsh conditions. They are commonly used in boats, off-road vehicles, and industrial machinery. A simple mistake in selecting a switch can lead to failures or damage. Many users overlook the importance of IP ratings. A higher IP rating ensures better protection against water and dust.

These switches not only enhance durability but also improve safety. However, improper installation can negate these benefits. Understanding their usage and application is crucial for optimal performance. As the market evolves, the need for innovation in waterproof designs remains significant.

What is a Waterproof Rocker Switch?

A waterproof rocker switch is a crucial component in various applications, especially in harsh environments. These switches are designed to prevent water intrusion and protect internal mechanisms. Typically made from durable materials, they often feature seals and casings that enhance their resistance to moisture and dust. According to a recent industry report, the global market for waterproof switches is expected to grow by over 7% annually due to increased demand in automotive and outdoor equipment sectors.

The key aspect of a waterproof rocker switch is its IP (Ingress Protection) rating. An IP65 rating, for example, means it is dust-tight and can withstand low-pressure water jets from any direction. This makes it suitable for outdoor lighting and marine applications. In contrast, a lower IP rating might not provide the same level of protection, increasing the risk of failure. Users should carefully consider the environment in which these switches will operate.

Tips: When selecting a waterproof rocker switch, check the IP rating. Higher ratings offer better protection. Ensure compatibility with the voltage and current of your application. Regularly inspect switches for wear and degradation; moisture can compromise performance over time. Users sometimes overlook these factors, leading to unexpected failures. Investing in quality components is paramount for longevity and reliability.

What is a Waterproof Rocker Switch and How is it Used?

| Feature | Description |

|---|---|

| Definition | A waterproof rocker switch is a type of electrical switch designed to operate under wet conditions, preventing water ingress. |

| Applications | Used in marine applications, outdoor lighting, and in equipment that requires protection from moisture. |

| Common Ratings | Typically rated for 10A at 12V or 5A at 24V, varying with manufacturer specifications. |

| Installation | Can be mounted on panels, requiring a cut-out for the switch body that matches its specifications. |

| IP Rating | Often rated IP65 or higher, indicating protection against dust and water splashes. |

Components and Design of Waterproof Rocker Switches

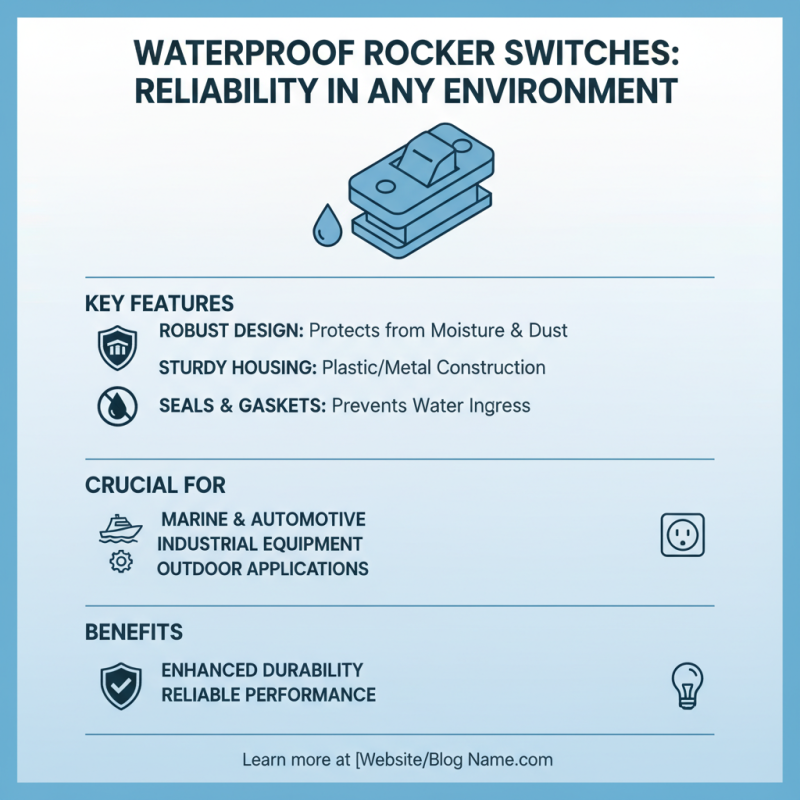

Waterproof rocker switches are crucial for various applications. They feature a robust design that protects internal components from moisture and dust. These switches typically include a sturdy housing made from materials like plastic or metal. Seals and gaskets are used to prevent water ingress, ensuring durability.

The internal components of waterproof rocker switches include a mechanism that allows for smooth operation. This mechanism often involves a simple toggle action. User interaction is easy, even with wet hands. There are also spring-loaded elements that provide tactile feedback. This makes it clear whether the switch is on or off. Some designs incorporate LED indicators that enhance visibility in low light.

Despite their many advantages, these switches can face challenges. Installation may require careful attention to seal integrity. An improper fit can lead to water exposure and failure. Additionally, some users may overlook the importance of regular maintenance. Dust and grime can accumulate over time. Understanding these factors is essential for optimal performance.

Common Applications of Waterproof Rocker Switches

Waterproof rocker switches are essential in various environments. They resist water, dust, and other contaminants. This makes them ideal for outdoor equipment and marine applications. For example, these switches often control lighting or motors in boats and off-road vehicles. According to a market research report, the global demand for waterproof rocker switches is expected to grow by 6.5% per year. This growth reflects increasing use in harsh conditions.

Common applications include automotive, industrial, and consumer electronics. In the automotive industry, these switches enhance safety by preventing accidental activation in wet conditions. Furthermore, in industrial settings, they endure extreme temperatures and heavy vibration. Research indicates that outdoor equipment uses waterproof switches to prolong lifespan and reduce failure rates. However, their reliability can vary. Not all switches meet the same standards, leading to potential risks.

In consumer electronics, waterproof rocker switches add convenience. They enable users to operate devices in wet environments, like kitchens or bathrooms. However, it's essential to choose appropriate ratings for voltage and current. Ignoring this can lead to device failure or safety hazards. Thus, while waterproof rocker switches offer many advantages, understanding specifications is crucial for effective use.

Installation Guidelines for Waterproof Rocker Switches

Waterproof rocker switches are essential in various applications, particularly in outdoor and marine settings. Installing these switches requires careful attention to detail. A study by the Institute of Electrical and Electronics Engineers (IEEE) highlighted that improper installation can lead to serious failures in sealing. This underscores the importance of precise installation guidelines.

When installing a waterproof rocker switch, ensure that the enclosure meets IP67 standards. This rating indicates total protection against dust and can withstand temporary submersion in water. Begin by selecting an appropriate location that minimizes exposure to harsh conditions. Before mounting, clean the surface thoroughly to enhance adhesion. Use a rubber or silicone gasket during installation for additional waterproofing.

Wiring is another critical aspect. Keep wires short and organized to avoid potential damage. Properly sealing connections with heat shrink tubing can prevent moisture ingress. In the end, it’s vital to test the switch rigorously after installation. Even minor errors in the installation process can lead to failure under pressure. Thus, attention to these guidelines can make a significant difference in performance and longevity.

Maintenance and Troubleshooting Tips for Waterproof Rocker Switches

Waterproof rocker switches are essential in environments exposed to moisture. They often face challenges like corrosion and wear. Regular maintenance is crucial for ensuring longevity. Cleaning the switch periodically helps prevent dust and dirt buildup. Use a soft cloth and mild cleaner. Avoid abrasive materials that could cause scratches.

If the switch begins to malfunction, it could be due to internal moisture. Inspect the area around the switch for signs of water ingress. Sometimes, simply drying it can fix the problem. However, if issues persist, deeper troubleshooting may be required. Test the circuit and check the connections. Faulty wiring can often lead to unexpected behavior.

Don’t forget about user habits. Over-switching or forceful operation can lead to premature failure. Educating users about gentle handling can extend the switch's life. Sometimes, we overlook these simple practices. In the end, proper care and user education are vital to maintaining the functionality of waterproof rocker switches.

Related Posts

-

The Future of Advanced Waterproof Rocker Switch Technology

-

Ultimate Guide to Choosing the Best Waterproof Rocker Switch for Your Needs

-

Waterproof Rocker Switches Shine at 137th Canton Fair with Record International Participation

-

Elevate Your Experience: The Global Success of Upgraded Chinese Manufacturing with Best Electrical Rockers

-

2025 Trends in Waterproof Toggle Switches and How to Choose the Best One

-

How to Find the Best Round Rocker Switch Manufacturer for Your Needs