Unlocking Efficiency and Safety with Electrical Rocker Benefits

In today's rapidly evolving technological landscape, the integration of advanced controls in industrial and consumer applications is paramount for enhancing efficiency and safety. One such innovation leading this charge is the Electrical Rocker, a versatile component that significantly streamlines operations across various sectors. According to a report by Research and Markets, the global market for electrical components is projected to reach $1 trillion by 2025, driven by the increasing demand for automation and smart devices. The Electrical Rocker not only simplifies the user interface but also minimizes the risk of operational hazards, showcasing how modern engineering solutions are transforming traditional practices. As industries strive for greater precision and reliability, understanding the benefits of Electrical Rockers becomes essential for maximizing productivity and ensuring a safe working environment.

Exploring the Key Advantages of Electrical Rockers in Modern Applications

Electrical rockers have emerged as a transformative solution in various modern applications, significantly enhancing efficiency and safety. According to a report by MarketsandMarkets, the global electrical switch market is expected to reach USD 75 billion by 2025, driven predominantly by the increasing demand for energy-efficient solutions. This growth highlights how electrical rockers, as integral components in control systems, are helping industries minimize energy wastage while optimizing operational performance.

Moreover, the integration of electrical rockers into safety systems is paramount. A study published by the National Safety Council indicates that electrical hazards account for approximately 10% of workplace injuries. By employing reliable electrical rockers designed with built-in safety features, companies can mitigate risks associated with accidental overloads or malfunctions. These rockers often include features such as overload protection and fail-safe mechanisms, providing a robust solution for environments that prioritize safety alongside efficiency. As industries continue to innovate and adopt smarter technologies, the role of electrical rockers in enhancing operational safety and efficiency cannot be overstated.

Maximizing Operational Efficiency with Advanced Electrical Rocker Systems

In today's fast-paced industrial environment, maximizing operational efficiency is more crucial than ever. Advanced electrical rocker systems provide a robust solution that enhances both productivity and safety in various applications. According to a recent report by the International Society of Automation, 65% of organizations implementing electrical rocker systems reported significant improvements in their operational workflows. These systems streamline processes, reduce manual intervention, and minimize the likelihood of human error, leading to remarkable gains in efficiency.

Tips for implementing electrical rockers effectively include conducting a thorough assessment of your existing operational processes to identify areas for improvement. Additionally, consider investing in training for your personnel to ensure they understand the system's functionalities fully. A report from the Electrical Safety Foundation International highlights that 30% of electrical accidents can be prevented with proper training, emphasizing the importance of safety in operational changes.

Another key to maximizing effectiveness with advanced electrical rockers is regular maintenance. The Maintenance Optimization Institute found that preventive maintenance can lead to a 25% reduction in downtime. By routinely checking the systems and components involved, businesses can sustain high efficiency levels while ensuring that safety standards are maintained.

Ensuring Worker Safety: How Electrical Rockers Mitigate Risks

In today's industrial landscape, the importance of worker safety cannot be overstated. Electrical rockers are emerging as pivotal tools in mitigating risks associated with machinery operation. These efficient devices enhance operational control, allowing workers to manage electric-powered machinery with precision. By providing a safer interface, electrical rockers reduce the likelihood of accidents caused by unintended activation or malfunctioning equipment.

To ensure optimal safety when using electrical rockers, it’s crucial to maintain them regularly. Regular inspections can identify wear and tear that may compromise functionality. Additionally, training workers on the proper use of electrical rockers is essential. Understanding how to respond in case of a malfunction can significantly reduce potential hazards.

Furthermore, integrating safety features, such as overload protection and emergency shut-off mechanisms, can enhance the functionality of electrical rockers. Employers should prioritize equipment that meets the latest safety standards, ensuring that the tools in use not only boost efficiency but also protect their workforce from unnecessary risk. These measures contribute to a safer working environment, ultimately leading to improved productivity and employee morale.

The Future of Control Mechanisms: Innovations in Electrical Rocker Technology

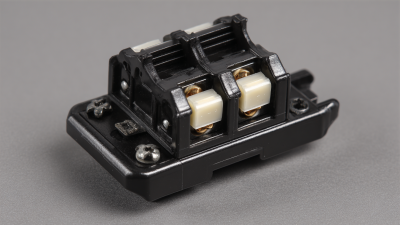

The evolution of control mechanisms has taken a significant leap forward with innovations in electrical rocker technology. Unlike traditional switches, electrical rockers offer a seamless blend of functionality and design, making them an ideal choice for modern applications. These mechanisms utilize advanced electronics to provide precise control, enabling users to manage various devices with the mere touch of a finger. The integration of smart technology allows for features such as programmable settings, timers, and even remote access, pushing boundaries of what we can expect from everyday controls.

In addition to enhancing user experience, electrical rockers promote safety and efficiency in operations. With built-in safety protocols, these devices minimize the risk of accidental activation, ensuring that equipment operates only when intended. Their compact design also allows for easier integration into existing systems without compromising on performance. As industries continue to embrace automation and smart technology, the role of electrical rockers is set to expand, providing a versatile solution that meets the demands of a rapidly changing technological landscape.

Unlocking Efficiency and Safety with Electrical Rocker Benefits - The Future of Control Mechanisms: Innovations in Electrical Rocker Technology

| Feature | Description | Benefit | Applications |

|---|---|---|---|

| Compact Design | Small footprint suitable for limited spaces. | Maximizes usability in constrained environments. | Automotive controls, Home appliances. |

| Enhanced Durability | Built to withstand harsh conditions. | Reduced maintenance costs and longer lifespan. | Industrial machinery, Outdoor equipment. |

| User-friendly Interface | Intuitive control layout for ease of use. | Improves user satisfaction and reduces training time. | Consumer electronics, Gaming devices. |

| Safety Features | Incorporates fail-safes and emergency stops. | Increases user confidence and reduces accidents. | Medical devices, Transportation systems. |

| Customizable Options | Variety in colors, sizes, and functionalities. | Flexibility to meet specific user needs. | Smart home technology, Personal gadgets. |

Cost-Effectiveness: Evaluating the Economic Benefits of Electrical Rockers

In recent years, the push for cost-effectiveness in engineering has led to innovative solutions in various sectors, particularly with the advent of electrical rockers. These devices have proven to be a game-changer by combining efficiency and safety, ultimately driving significant economic benefits for industries that rely on precise control mechanisms. The advancements in design, such as the recent development of a 2-Step rocker arm, showcase how analytical tools and rigorous physical testing can enhance product reliability while reducing costs associated with traditional systems.

The economic advantages of using electrical rockers can be seen in their reduced maintenance requirements and improved operational efficiency. By minimizing mechanical wear and tear through effective design, companies can achieve lower downtime and maintenance costs. Furthermore, the design innovations, like those presented in the new 2-Step rocker arm, highlight the potential for creating more adaptable systems that respond swiftly to changing operational demands. This flexibility not only enhances productivity but also aligns with the industry's overarching goal of achieving sustainable growth while maximizing economic returns.

Cost-Effectiveness of Electrical Rockers

Related Posts

-

Elevate Your Experience: The Global Success of Upgraded Chinese Manufacturing with Best Electrical Rockers

-

Exploring Innovative Alternatives to the Best Double Rocker Switch for Your Projects

-

Premium Quality Momentary Rocker Switches from a Leading Chinese Manufacturer

-

Innovative Solutions for Best Round Rocker Switch Applications

-

Unleashing Excellence: Premium Micro Switch Push Buttons from China for Global Buyers

-

Leading Push Button Starter Switch Manufacturers in China at the 137th Canton Fair