Momentary Push Button Switch Tips for Better Performance?

The Momentary Push Button Switch is a vital component in many devices today. This simple switch enables users to control functions with ease. However, achieving optimal performance often requires attention to detail.

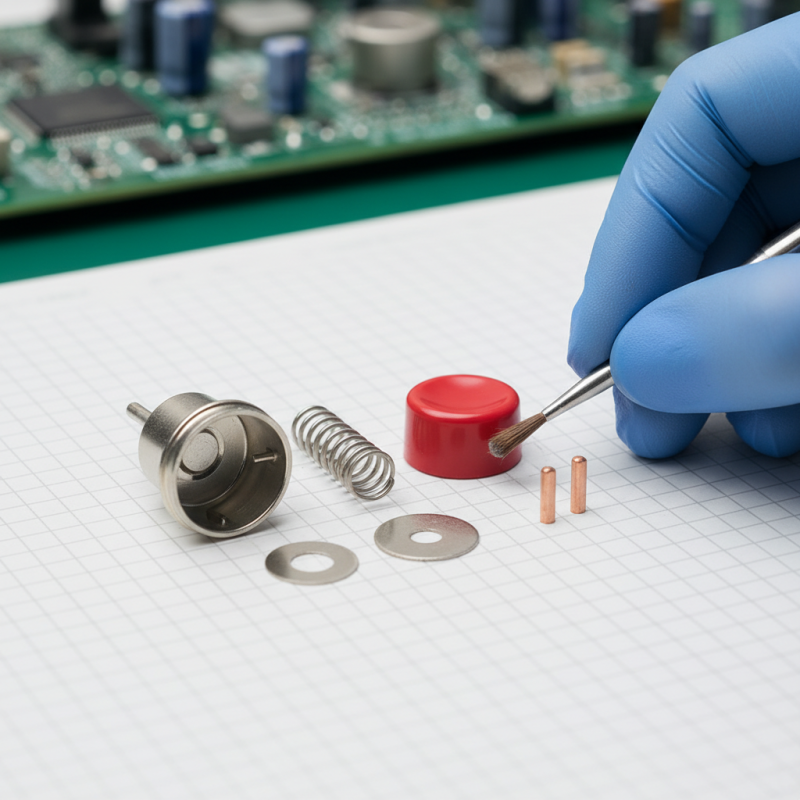

Proper installation plays a key role in ensuring reliability. Make sure contacts are clean. Misalignment can lead to malfunction, affecting the entire system. Testing after installation is equally important. Regular checks can prevent severe issues later on.

Moreover, choosing the right materials matters. Not all Momentary Push Button Switches are created equal. Some may wear out quickly, while others will last. Researching specifications can help in making better choices. Remember, a small detail can make a significant difference in performance. Aim for perfection, but also accept that improvements are always possible.

Understanding Momentary Push Button Switches and Their Applications

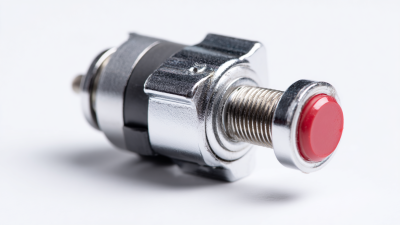

Momentary push button switches are common in various devices. They operate with a simple press and release mechanism. These switches find their use in remote controls, appliances, and machinery. Understanding their function can enhance device performance.

These switches can sometimes be misleading. They might seem straightforward, but the quality varies widely. A poorly designed switch may fail to respond correctly. This can lead to user frustration. Sometimes, they stick or do not make proper contact, leading to inconsistent performance.

In terms of applications, momentary switches are versatile. They can trigger lights, start motors, or send signals. However, it’s crucial to consider their placement. Ergonomics play a key role in their effectiveness. A switch that is difficult to reach can hinder functionality. Testing different designs is essential to find the right fit for your needs.

Momentary Push Button Switch Tips for Better Performance

| Dimension | Specification | Common Applications | Recommended Use Cases |

|---|---|---|---|

| Voltage Rating | 12V, 24V, 120V | Home appliances, Automation systems | Use in low-power devices |

| Current Rating | 1A, 2A, 5A | Sound systems, Lighting control | Ideal for triggering events |

| Material | Plastic, Metal | Industrial controls, DIY projects | Choose based on environment |

| Actuation Style | Momentary, Latching | Gaming consoles, Tools | Select based on function |

Key Factors Influencing the Performance of Push Button Switches

When it comes to push button switches, performance hinges on several critical factors. The durability of these switches is paramount. According to industry reports, switches are expected to endure up to 1 million cycles. However, many fall short of this expectation, primarily due to material quality. Selecting high-grade materials can improve longevity significantly. For example, using stainless steel contacts instead of cheaper alternatives can increase reliability.

Another essential factor lies in the actuation force. Data suggests that a force between 5N to 10N is optimal for user comfort and operational efficiency. Switches that are too stiff can lead to user fatigue. Conversely, those that are too loose may fail to register inputs accurately. This delicate balance is crucial for manufacturers aiming for peak performance.

Environmental conditions also play a role. Exposure to dust, moisture, and extreme temperatures can degrade switch performance over time. Reports indicate that switches exposed to adverse conditions may have a 30% higher failure rate. Engineers must consider these elements when designing switches. A failure to do so could lead to misunderstandings and operational inefficiencies. Testing for these variables is often overlooked, but it is a necessary step in ensuring longevity.

Best Practices for Installing Momentary Push Button Switches

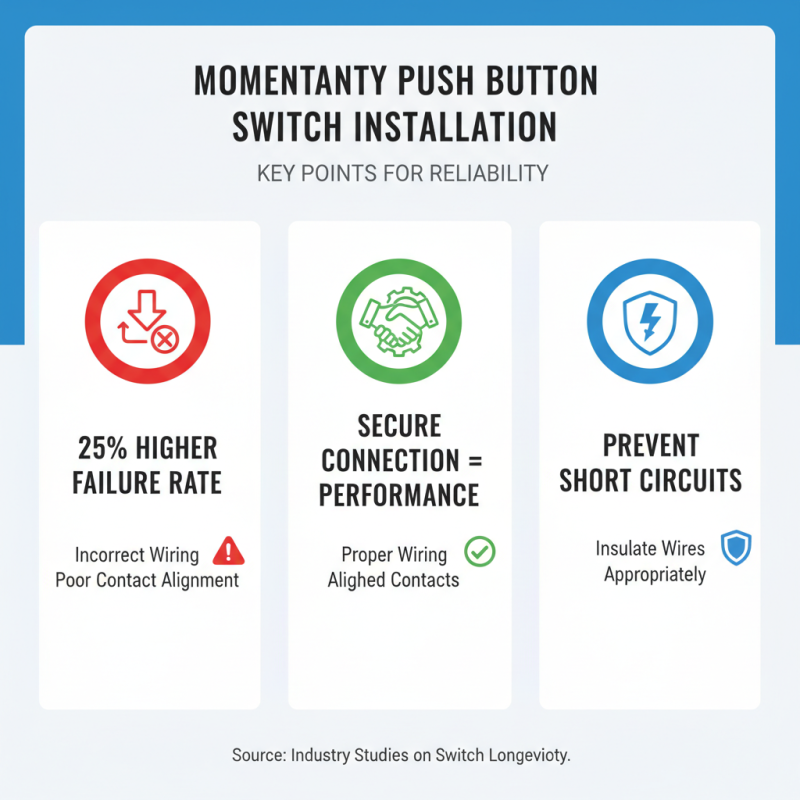

When installing momentary push button switches, attention to detail is crucial. Studies show that incorrect installation can lead to a 25% increase in failure rates. This is often due to improper wiring or poor contact alignment. A secure connection is vital for reliable performance. Insulating the wires appropriately can prevent short circuits, which can cause unexpected failures.

Using the right tools will enhance the installation process. It’s important to use a torque screwdriver for tightening screws, as overtightening can damage the switch. Many technicians overlook this aspect, leading to a higher likelihood of switch malfunction. Furthermore, ensuring that the switch is rated for the load it will handle is essential. According to recent industry analyses, switches that exceed their load ratings are 40% more prone to burnout.

Real-world testing reveals that regular maintenance can prolong the life of push button switches. Keeping the surrounding area clean and free from dust can significantly affect their performance. A surprisingly high percentage of failures stem from external debris affecting operation. It’s also beneficial to perform routine checks on button responsiveness, noting any hesitance. Regular monitoring helps identify weaknesses early on, allowing for timely replacements.

Troubleshooting Common Issues with Push Button Switches

Push button switches are common in many devices. Yet, they often present issues. A switch may stick or fail to respond. This can be frustrating for users. Sometimes, the problem lies in dirt or dust buildup interference. Regular cleaning can help mitigate this.

Another common issue is inconsistency in performance. A switch might work intermittently. This could be due to worn contacts. Users should check the switch for any signs of damage or wear. Replacing a worn switch may solve performance problems.

Loose connections can also cause failures. Ensure that all wiring is secure. A poorly connected wire might lead to erratic behavior. Occasionally, reflection on the entire setup is necessary. Are the components compatible? Is the power supply adequate? Addressing these questions can lead to better performance.

Maintenance Tips for Prolonging the Life of Push Button Switches

Push button switches are essential in many devices. They control everything from lights to machines. Proper maintenance is key for their longevity. Regular cleaning helps eliminate dust and debris. Dirt can obstruct the switch, causing poor performance. Use a dry cloth to wipe the surface. Avoid harsh chemicals that may damage the components.

Inspect the wiring connected to the switch periodically. Loose or frayed wires can lead to malfunction. Ensure connections are tight and secure. If you notice any issues, address them immediately. It’s better to fix small problems than face bigger ones later. Keep an eye on the switch's responsiveness. If it becomes sticky or unresponsive, it might need replacement.

Over time, wear and tear is inevitable. Using a switch beyond its capacity can accelerate its decline. Sometimes less is more. Avoid excessive force when pressing the button. Gentle taps can extend its life significantly. Reflect on your usage habits. Are you pushing the switch too hard? Rethinking this could prevent future problems.

Related Posts

-

Exploring the Future of Smart Technology: How Illuminated Push Buttons Enhance User Experience

-

Leading Push Button Starter Switch Manufacturers in China at the 137th Canton Fair

-

5 Best Momentary Push Button Switches for Enhanced Device Performance in 2023

-

2026 Top Illuminated Push Button Features You Should Know?

-

How to Choose the Right Momentary Push Button Switch for Your Project

-

10 Essential Tips for Choosing the Perfect Push Button Starter Switch