Illuminate Your Control Experience with the Advantages of Illuminated Push Buttons for Enhanced Safety

In today's fast-paced industrial environments, the importance of user-friendly control interfaces cannot be overstated. The integration of Illuminated Push Buttons has proven to be a game-changer, enhancing not only operational efficiency but also safety standards. According to a report by the International Safety Equipment Association (ISEA), nearly 40% of workplace accidents related to equipment operation can be traced back to poor visibility and inadequate control indicators. Illuminated Push Buttons address these concerns by providing clear visual feedback, which is essential in emergency situations or low-light conditions. Moreover, a study by MarketsandMarkets predicts a significant growth in the human-machine interface market, driven by the increasing demand for safety-compliant equipment, where illuminated controls are expected to play a pivotal role. By illuminating your control experience with these advanced buttons, organizations can significantly reduce error rates and improve overall safety protocols.

Understanding the Importance of Visibility in Control Systems

In modern control systems, visibility is paramount for ensuring safety and efficiency. Illuminated push buttons serve as a critical interface between operators and machinery, directly impacting the effectiveness of control operations. According to a report by the National Safety Council, as much as 70% of workplace accidents are attributed to human error, often stemming from poor visibility and miscommunication. Illuminated controls can significantly reduce these errors by providing immediate visual cues that signal the status of equipment and systems.

Moreover, research published by the International Society of Automation indicates that visibility enhances not only safety but also productivity. The study found that operators were able to complete tasks 30% faster when using illuminated buttons due to the instant recognition of control states. This efficiency gain illustrates the importance of integrating visibility into design standards, ensuring that safety measures are not just reactive but also proactive in preventing accidents. As industries continue to evolve, the role of illuminated push buttons in creating user-friendly and error-resistant environments will become increasingly essential.

Illuminated Push Buttons: Enhancing Safety and Visibility in Control Systems

This chart illustrates the significant advantages of using illuminated push buttons in control systems, focusing on key factors such as Visibility, Safety, User Engagement, and Response Time.

Key Benefits of Illuminated Push Buttons for Enhanced Safety

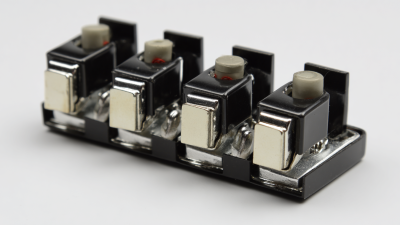

Illuminated push buttons offer a range of advantages that significantly enhance safety in various environments. One of the primary benefits is the improved visibility they provide in low-light or high-stress situations. The bright illumination of these buttons allows operators to quickly identify the correct control, reducing the risk of errors in critical moments. This is particularly crucial in industrial settings or emergency situations where quick, correct action can prevent accidents and ensure safety.

Moreover, illuminated push buttons can serve as visual indicators for system status. For instance, different colors can signify various operational states, such as green for 'operational' and red for 'emergency stop.' This feature not only enhances user awareness but also promotes a more intuitive interaction with machines and devices. As operators become accustomed to the signaling provided by illuminated buttons, their response times improve, further contributing to a safer working environment. By integrating illuminated push buttons into control systems, organizations can prioritize safety while streamlining operational efficiency.

Illuminate Your Control Experience with the Advantages of Illuminated Push Buttons for Enhanced Safety

| Feature | Description | Safety Benefit |

|---|---|---|

| Visibility | Illuminated push buttons provide clear visual cues in low light conditions. | Reduces the risk of operator errors in dim environments. |

| Feedback | Lighting changes provide instant feedback on the status of the system. | Enhances operator awareness and decision-making. |

| Color Coding | Different colors can indicate various functions or statuses. | Facilitates quick identification of control functions and status. |

| Durability | Built to withstand harsh industrial environments. | Reduces likelihood of equipment failure and promotes safety. |

| Customizability | Options for different sizes and illumination styles to suit various applications. | Ensures optimal use and improves safety protocol adherence. |

Choosing the Right Type of Illuminated Push Buttons for Your Needs

When selecting illuminated push buttons, it is crucial to consider the specific needs of your application. These buttons not only enhance visibility and safety in dark environments but also serve as intuitive indicators of system status. For instance, if you are designing a control interface for industrial machinery, a push button with a bright LED might signal operational readiness, helping to prevent accidents caused by unclear signals.

Moreover, illuminated push buttons come in various types, including momentary and latching configurations. Momentary buttons, which only stay lit while pressed, are ideal for temporary actions such as machine activation, providing immediate feedback to users. Conversely, latching buttons can maintain their illuminated state until manually switched off, making them suitable for indicating prolonged operational states or alerts. Understanding these differences will empower you to select the perfect button for your control experience, ensuring both functionality and safety.

Best Practices for Installing Illuminated Push Buttons Effectively

When integrating illuminated push buttons into industrial settings, adhering to best practices during installation is crucial for maximizing safety and functionality. According to a report by the National Safety Council, over 200,000 workplace injuries arise from equipment malfunctions, highlighting the importance of clear visibility in control systems. Illuminated push buttons provide a vital enhancement, offering both visual feedback and intuitive operation, especially in low-light environments.

Proper installation begins with placing illuminated push buttons at ergonomic heights and ensuring their brightness is adjustable based on ambient lighting conditions. The Illuminating Engineering Society recommends a minimum brightness of 100 lux for safe operation in most industrial spaces. Furthermore, utilizing color coding—such as red for emergency stops and green for operational controls—can significantly reduce the likelihood of operator error. Reports from the International Electrotechnical Commission suggest that color differentiation improves response times by up to 40%, underlining the strategic choice of illumination in enhancing user experience and safety in the workplace.

Maintaining and Troubleshooting Your Illuminated Control Solutions

Illuminated push buttons not only enhance user experience but also play a pivotal role in safety and control applications. When it comes to maintaining these illuminated control solutions, regular inspections and proper cleaning are essential. Dust and grime accumulation can hinder visibility and functionality, so ensuring buttons are free from obstructions will help preserve their intended purpose. Routine checks on the wiring and connections can prevent electrical failures and provide peace of mind.

Troubleshooting illuminated push buttons can often be straightforward if you approach it methodically. Begin by testing the power supply to ensure the circuit is functioning correctly. If the button remains unresponsive, examine the push button itself for any signs of damage or wear. Additionally, it’s crucial to evaluate the LED components; a burnt-out bulb can easily be replaced and will restore the button's visibility. By implementing these maintenance and troubleshooting practices, you can ensure that your illuminated control solutions operate smoothly, contributing to a safer and more efficient work environment.

Related Posts

-

Ultimate Checklist for Sourcing the Best Push Button On Off Switches Worldwide

-

Unleashing Excellence: Premium Micro Switch Push Buttons from China for Global Buyers

-

Exploring the Features and Applications of Best Illuminated Push Buttons with a How to Guide

-

15 Best Push Button On Off Solutions for Global Buyers

-

7 Reasons to Choose the Best Dpdt Rocker Switch for Your Next Project

-

Top Strategies for Enhancing Home Automation with Rocker Light Switches