How to Choose the Right Momentary Push Button for Your Project

In the world of electronic components, selecting the appropriate Momentary Push Button is crucial for the success of any project, whether it be for consumer electronics, industrial applications, or DIY designs. According to a recent market analysis by Grand View Research, the global push button switch market is projected to reach USD 1.5 billion by 2028, indicating a growing demand for reliable and efficient switching solutions. Momentary Push Buttons, in particular, are favored for their versatility and ease of use, allowing designers to implement functionality such as start/stop mechanisms, toggling functions, and various interactive interfaces. Understanding the technical specifications, such as actuation force, lifespan, and sealing ratings, is essential in making an informed decision that aligns with your project's requirements. This blog will guide you through the critical considerations to ensure you choose the right Momentary Push Button for your specific application.

Understanding Momentary Push Buttons: Types and Applications

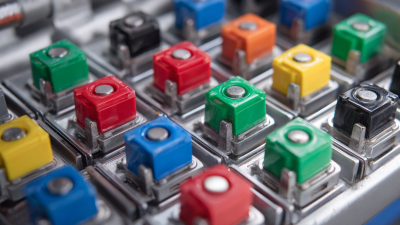

When selecting momentary push buttons for your project, understanding the various types and their applications is crucial. Momentary push buttons can be categorized into two main types: normally open (NO) and normally closed (NC). According to a report by MarketsandMarkets, the global push button switch market was valued at approximately $1.5 billion in 2022 and is projected to reach $2.2 billion by 2027, reflecting the increasing demand in various industries such as automotive, consumer electronics, and industrial automation.

When selecting momentary push buttons for your project, understanding the various types and their applications is crucial. Momentary push buttons can be categorized into two main types: normally open (NO) and normally closed (NC). According to a report by MarketsandMarkets, the global push button switch market was valued at approximately $1.5 billion in 2022 and is projected to reach $2.2 billion by 2027, reflecting the increasing demand in various industries such as automotive, consumer electronics, and industrial automation.

Each type of momentary push button serves different functions. Normally open buttons connect the circuit only when pressed, making them ideal for applications like machine start controls and electronic devices. In contrast, normally closed buttons are used to interrupt a circuit; they can serve safety functions, such as emergency stop buttons in industrial settings. A study published by Research and Markets noted that robust growth in the manufacturing sector is driving the need for reliable interface components like push buttons, emphasizing their critical role in enhancing user interaction and machine safety across applications.

Key Factors to Consider When Selecting a Momentary Push Button

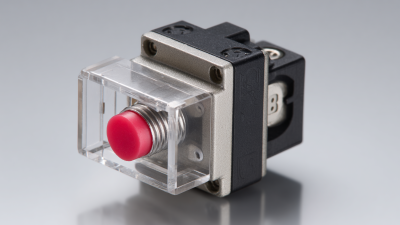

When selecting a momentary push button for your project, several key factors come into play to ensure optimal performance and durability. One of the primary considerations is the button's mechanical lifespan, which is often quantified by the number of actuations it can handle before failure. According to industry reports, high-quality momentary push buttons can exceed 1 million cycles, making them suitable for demanding applications. Evaluating the lifespan of different models helps ensure reliability and reduces replacement costs over time.

In addition to lifespan, the button's electrical rating is crucial. This rating, usually specified in terms of voltage and current, determines the maximum load the push button can handle without compromising functionality. For instance, a report from the Electronics Components Industry Association indicates that push buttons designed for high-power applications can manage loads upwards of 10A at 250V AC. Ensuring that the momentary push button meets or exceeds your project's electrical requirements is vital for safety and performance.

Finally, considering environmental factors—such as exposure to moisture, dust, or temperature extremes—will influence the selection process. Momentary push buttons are often rated for varying ingress protection (IP) levels, with IP65 and IP67 being common standards for rugged conditions. Choosing an adequately rated button ensures longevity and reliability in challenging environments, enhancing the overall success of your project.

Momentary Push Button Selection Factors

Exploring Different Switch Mechanisms: Tactile vs. Non-Tactile

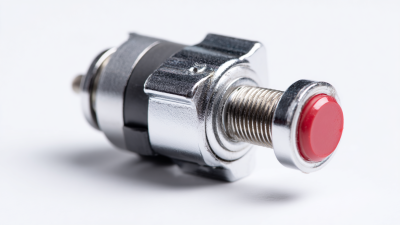

When it comes to selecting a momentary push button for your project, understanding the distinction between tactile and non-tactile switches is crucial. Tactile switches provide users with a noticeable feedback through a slight "click" when actuated, which can enhance the overall user experience. According to a report by Future Market Insights, the tactile switch market is expected to grow at a CAGR of approximately 6.4% from 2021 to 2031, owing to the increasing demand for user-friendly interface devices across various industries.

On the other hand, non-tactile switches, often referred to as silent or membrane switches, do not provide this feedback. They are typically preferred in applications where noise reduction is essential, such as in medical equipment or household appliances. Research conducted by MarketsandMarkets suggests that the non-tactile switch segment will see substantial growth as industries prioritize sleek designs and silent operations, projecting a market value of over $3 billion by 2025. Understanding the specific demands of your project will ultimately guide your choice between these two types of switch mechanisms, ensuring optimal functionality and user satisfaction.

How to Choose the Right Momentary Push Button for Your Project - Exploring Different Switch Mechanisms: Tactile vs. Non-Tactile

| Switch Type | Mechanism | Feedback Type | Lifespan (Cycles) | Typical Applications |

|---|---|---|---|---|

| Tactile | Mechanical | Positive feedback | 50,000 - 100,000 | Consumer electronics, keyboards |

| Non-Tactile | Membrane | No feedback | 1,000,000 - 10,000,000 | Remote controls, appliances |

| Tactile | Dome switch | Feedback on actuation | 500,000 - 1,000,000 | Toys, hand-held devices |

| Non-Tactile | Capacitive touch | No tactile response | 10,000,000+ | Smartphones, tablets |

How Aesthetics and Design Influence Push Button Choices

When selecting a momentary push button for a project, aesthetics and design play a crucial role. The ergonomic and visual appeal of a button can significantly impact user interaction. According to a study by the Nielsen Norman Group, 94% of first impressions are based on design, highlighting the importance of incorporating aesthetically pleasing elements. This can enhance user satisfaction and encourage more frequent use of the device.

Recent developments in user interface design, such as the upcoming update from a leading technology company that aims for a significant overhaul after many years, illustrate how increased complexity can inadvertently affect usability. Observers have noted that while striving for modernity, the new design bears a striking resemblance to older systems, which raises questions about readability and ease of navigation. A report from the Interaction Design Foundation states that usability issues frequently stem from poor design choices, emphasizing the need for intuitive aesthetics when selecting buttons.

Ultimately, choosing the right momentary push button involves balancing practical functionality with an appealing design that fosters better user experiences.

Common Mistakes to Avoid When Choosing Push Buttons for Projects

Choosing the right momentary push button for your project can be a daunting task, especially with the variety available on the market. One common mistake is to focus only on the aesthetic appearance of the button without considering its functional specifications. It's crucial to assess the electrical ratings, such as voltage and current, to ensure that the button can handle the required load. Overlooking these technical details can lead to performance issues or even component failure during your project's operation.

Another frequent pitfall is the disregard for the physical environment where the button will be used. Factors such as temperature fluctuations, humidity, and exposure to dust or water can significantly affect the longevity and reliability of the button. Selecting a push button that is not rated for harsh conditions can cause premature wear or malfunction. Additionally, ensure that the button's size and mounting style fit well within your design specifications, as an ill-fitting component can complicate installation and usability. By avoiding these common mistakes, you can make a more informed decision that enhances the performance and durability of your project.

Related Posts

-

Innovative Solutions for Best Micro Switch Push Button Applications

-

Ultimate Checklist for Sourcing the Best Push Button On Off Switches Worldwide

-

2025 Industry Insights: Ultimate Checklist for Selecting the Best Micro Switch Push Buttons

-

Exploring the Features and Applications of Best Illuminated Push Buttons with a How to Guide

-

What is a Micro Switch Push Button and How it Enhances Device Performance in Automation

-

5 Best Momentary Push Button Switches for Enhanced Device Performance in 2023