How to Choose the Right Micro Switch Button for Your Project

When embarking on a project that requires precise control, selecting the right Micro Switch Button is crucial. These buttons serve as the interface for user interaction in various devices. They come in different shapes, sizes, and functions, making it essential to understand what you need before making a decision.

Consider the application of the Micro Switch Button in your design. Will it be used in a high-frequency environment? Is it exposed to dust or moisture? These factors will influence your choice significantly. Exploring various options can be overwhelming. Each model may offer distinct advantages and disadvantages that are not immediately apparent.

Sometimes, the specifications can be confusing. Manufacturers often highlight features that sound impressive but may not suit your project. It’s essential to reflect on your specific requirements. Take the time to evaluate the trade-offs. A button that looks appealing might not perform well in real-world conditions. Clarifying your needs will lead to a more informed choice.

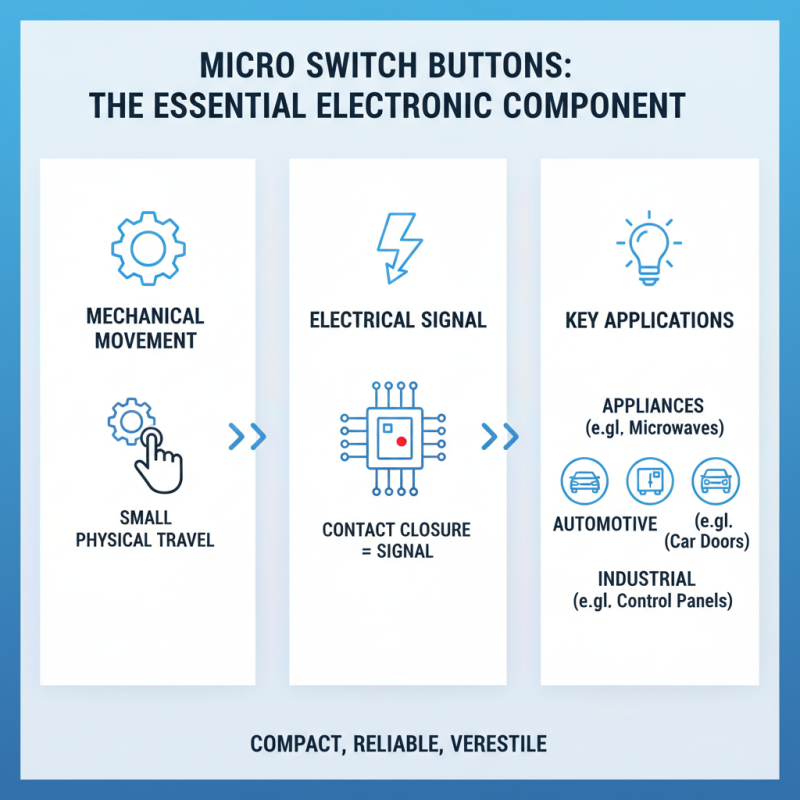

Understanding Micro Switch Buttons and Their Applications

Micro switch buttons are crucial in many electronic applications. These buttons couple a small mechanical movement with an electrical signal. They are commonly found in appliances, automotive systems, and industrial equipment. Understanding their functionalities will help you choose the right one for your project.

When selecting a micro switch, consider the operational force needed. Different projects require various sensitivity levels. Some applications may not respond to lower force switches, while others might be too sensitive to higher forces. This mismatch can lead to failures or inefficiencies. Pay attention to size and mounting options. Not all switch designs fit every project. Carefully review the specifications.

Environmental factors are also important. Moisture, dust, and temperature can impact performance. Calculate these conditions to ensure longevity. Testing prototypes in real conditions is key. You may find the theoretical choice does not perform as expected. Adjustments may be necessary. Consider the intended user interaction. Feedback from the button is essential for usability. Missteps in this phase can lead to frustrating user experiences.

Key Factors to Consider When Selecting a Micro Switch Button

When selecting a micro switch button for your project, several key factors must be considered. The operating force is crucial; it should align with your application’s requirements. According to industry reports, the ideal force often ranges from 0.5 to 5 Newtons. This ensures ease of use without compromising reliability.

The lifespan and endurance of the micro switch significantly impact its performance. Many switches are rated for up to a million cycles. However, installing them in environments with dust or moisture can severely reduce their lifespan. Regular maintenance can help identify early signs of wear.

Tip: Always check the switch's ratings to match your project specifications. Consider testing different forces during a prototype phase to gather user feedback. Remember that not every option is perfect; some switches may have inconsistent activation. Testing is essential to find the right fit for your specific needs.

Micro Switch Button Characteristics Comparison

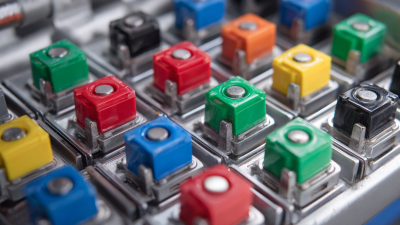

Types of Micro Switch Buttons and Their Unique Features

When selecting a micro switch button, understanding the types available can significantly enhance your project. The two most common types are the basic single-pole and double-pole switches.

Single-pole switches manage on-off functions with only one circuit. They are simple and compact, making them ideal for straightforward applications. In contrast, double-pole switches control two circuits simultaneously. This feature is useful in situations where you need to manage multiple functions at once.

Another important aspect is the actuator style. Roller lever, for instance, provides smooth operation. It can efficiently engage when needed. Tactile switches, on the other hand, give a clear click feeling when pressed. This feedback is beneficial for user interaction but might lead to overuse or wear. Each actuator has its advantages and disadvantages. Considering the environment is key; a waterproof option may be necessary for outdoor applications. Hence, misjudging the type can lead to unnecessary failures.

It’s also crucial to assess the switch ratings. Choosing a switch with insufficient ratings can lead to overheating or malfunction. This is an area where many projects fall short. Misunderstanding specifications can result in product failure. Testing different types in prototypes can uncover hidden issues early on. Remember, attention to detail and proper research can save time and resources.

Compatibility and Integration with Your Project Design

When selecting a micro switch button for your project, compatibility is crucial. The switch must fit the design specifications. Consider the voltage and current ratings. According to industry reports, improper ratings can lead to device failures. For instance, a mismatch in current capacity may result in overheating or malfunction.

Integration also matters greatly. Ensure that the micro switch can seamlessly connect with existing components. Review the physical dimensions as well. Many designs overlook size, leading to complications during assembly. A common issue involves clearance space. A switch that is too large can create installation challenges.

Tips: Always check compatibility chart data before finalizing your selection. A slight oversight can lead to performance issues. Involve team members in the decision-making process to gain diverse insights. Testing prototypes can reveal unforeseen problems. Adapting designs in early stages is easier than making changes later. Communication with suppliers can uncover valuable information to guide your choice.

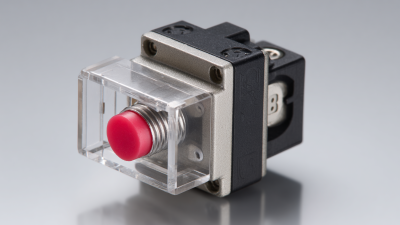

Testing and Quality Assurance for Micro Switch Buttons

When selecting micro switch buttons, testing and quality assurance play critical roles. A button's reliability and responsiveness can significantly impact your project's success. Therefore, rigorously testing each button is essential. This includes checking the actuation force and ensuring the switch activates smoothly. Pay attention to the tactile feedback; a poor tactile response might indicate a subpar product.

It's vital to assess durability as well. Life cycles can vary widely. Some switches might fail after just a few thousand clicks, while others last much longer. Conducting stress tests can help predict performance over time. Additionally, consider environmental factors. Exposure to moisture, dust, or extreme temperatures can affect functionality. Documents detailing testing results are highly beneficial for ensuring compliance with quality standards.

Finally, don't forget to assess the overall fit for your application. An overlooked aspect is the switch's mounting style. It should align perfectly with your design. Future iterations of your project may require adjustments based on feedback and test outcomes. It's important to remain open to making changes. Not all chosen switches will fit perfectly the first time around. Continuous evaluation and adaptation lead to more reliable products.

Related Posts

-

The Rise of Push On Off Switch Technology in Smart Home Automation Systems

-

2025 Top Push On Off Switch Features Benefits and Buying Guide

-

Innovative Solutions for Best Micro Switch Push Button Applications

-

2025 Industry Insights: Ultimate Checklist for Selecting the Best Micro Switch Push Buttons

-

What is a Micro Switch Push Button and How it Enhances Device Performance in Automation

-

How to Choose the Right Momentary Push Button for Your Project