How to Choose the Right Momentary Push Button Switch for Your Project

When embarking on an electronics project, one crucial component that often plays a pivotal role is the Momentary Push Button Switch. This seemingly simple device is designed to close or open an electrical circuit only while it's being pressed, making it an indispensable element in many applications ranging from home appliances to complex industrial systems. Understanding the nuances of selecting the right Momentary Push Button Switch can significantly influence the functionality and user experience of your project.

Choosing the appropriate switch involves considering various factors such as the switch’s design, electrical specifications, and usage environment. Whether you require a tactile feedback switch for a control panel or a sleek, unobtrusive option for a modern device, the choices are abundant and varied. Each type serves different purposes and comes with its own set of attributes, which can ultimately affect the performance and reliability of your project. Thus, familiarizing yourself with these aspects ensures you make an informed decision tailored to your specific needs, ensuring the success of your electronic venture.

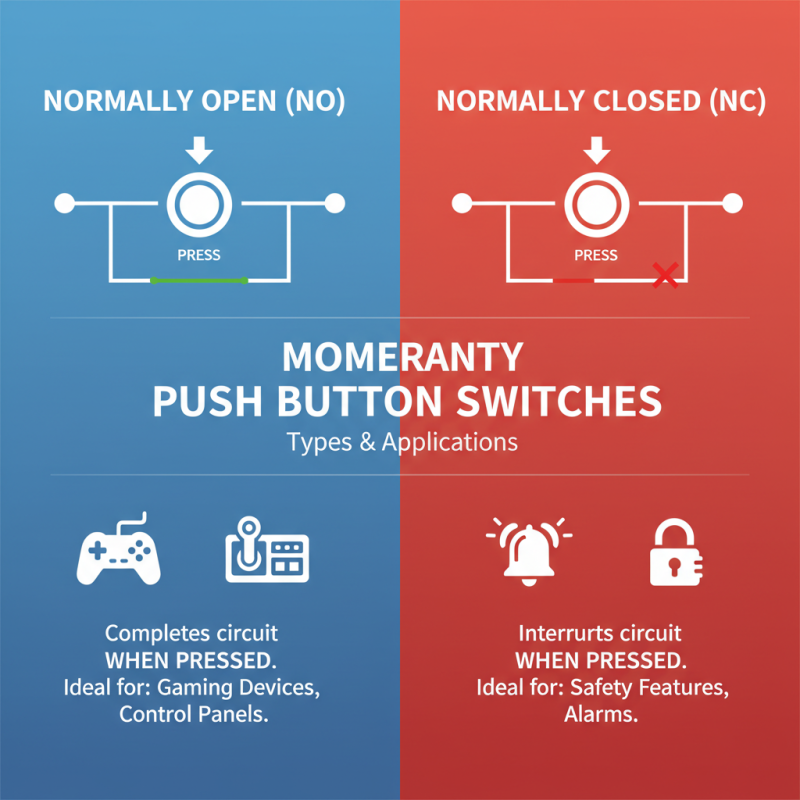

Understanding Types of Momentary Push Button Switches and Their Applications

When selecting a momentary push button switch for your project, it is essential to understand the various types available and how their unique features align with your specific application. Momentary push button switches can generally be classified into two main types: normally open (NO) and normally closed (NC). The normally open switches complete the circuit only when pressed, making them ideal for applications like gaming devices or control panels where a temporary action is needed. In contrast, normally closed switches interrupt the circuit when pressed, commonly used for safety features or alarms, ensuring a device is activated only under certain conditions.

Another important factor to consider is the button's physical characteristics, including size, shape, and actuation force. Different applications require different tactile feedback and aesthetics; for example, heavier actuation switches are preferable in environments where accidental activation must be minimized. Additionally, the materials and ratings of the switch, such as IP ratings for dust and water resistance, should be assessed based on the intended environment. Understanding these distinctions helps ensure that the selected switch not only performs its function effectively but also integrates seamlessly into the overall design of the project.

Key Specifications to Consider When Selecting a Momentary Push Button Switch

When selecting a momentary push button switch for your project, it is crucial to consider several key specifications that can significantly impact performance and reliability. One of the primary features to evaluate is the electrical rating of the switch, which includes voltage and current specifications. According to industry reports, excessive voltage or current can lead to switch failure or reduced lifespan. A typical range for momentary push button switches is between 12V-250V, accommodating various applications from DIY electronics to industrial control panels.

Another essential specification is the switch's actuation force, defined as the amount of pressure required to activate the switch. Studies indicate that the ideal actuation force varies depending on user comfort and application needs, typically ranging from 100 to 300 grams. Too little force may cause unintended activations, while too much can hinder ease of use. Additionally, the switch's mechanical life, often quantified in cycles, should be a consideration; high-quality switches generally offer a mechanical lifespan of 1 million cycles or more, ensuring durability and reliability over time.

Lastly, environmental considerations play a pivotal role in the selection process. Momentary push button switches are available in various environmental ratings, including IP ratings for ingress protection. An IP rating of IP65, for instance, indicates the switch's resistance to dust and water jets, making it suitable for outdoor or industrial environments. As reported by major market analysis firms, the growth in automation and the need for reliable user interfaces in challenging conditions underscore the importance of these specifications in choosing the right momentary push button switch for your project.

Assessing Load Requirements for Push Button Switches in Electronic Projects

When selecting a momentary push button switch for an electronic project, assessing the load requirements is fundamental. The first step is to understand the voltage and current specifications that the switch will need to handle. This involves evaluating the overall circuit design and identifying the maximum load that the push button will control. Ensuring that the switch can manage this load without failing is crucial for the reliability of the project. For instance, a switch that operates at a higher voltage and current rating than the requirements can prolong lifespan and prevent overheating.

Another important aspect to consider is the switch's duty cycle. This refers to the frequency with which the switch will be activated during its operation. Frequent use may necessitate a switch designed for higher durability and responsiveness. It's also essential to consider the environment in which the switch will operate. Factors such as temperature, humidity, and potential exposure to contaminants can influence switch performance. By carefully assessing these load requirements and environmental conditions, you can select a momentary push button switch that not only fits your project but also ensures optimal functionality and longevity.

Load Requirements for Momentary Push Button Switches

Evaluating Durability and Lifespan: Ratings for Momentary Push Button Switches

When selecting a momentary push button switch for your project, evaluating the durability and lifespan is crucial. Momentary switches often undergo repeated use, and their longevity can greatly impact the overall efficiency of your design. A common metric used in the industry to assess durability is the number of actuations the switch can withstand before failure. According to industry reports, high-quality momentary switches typically offer ratings ranging from 100,000 to 10 million cycles, depending on their design and materials. Therefore, understanding the expected usage in your application helps in choosing a switch that meets the required durability standards.

In addition to the number of cycles, environmental factors also play a significant role in the lifespan of momentary push button switches. Factors such as temperature, humidity, and exposure to chemical agents can affect the switch's performance and durability. For instance, a report by an industry research group indicated that switches designed for harsh environments could maintain functionality while operating in extreme conditions, with some rated for temperatures between -40°C to 85°C. This information is pertinent for projects that require reliable performance in challenging settings, ensuring that the selected switch will not fail prematurely under specified conditions.

Best Practices for Wiring and Mounting Momentary Push Button Switches in Projects

When selecting momentary push button switches for your projects, proper wiring and mounting practices are crucial to ensuring functionality and longevity. According to a report by MarketsandMarkets, the global market for push button switches is projected to grow at a compound annual growth rate (CAGR) of 4.3% from 2021 to 2026. This growth underscores the importance of understanding how to effectively incorporate these components into your designs.

When wiring momentary push button switches, it is essential to plan your circuit layout carefully. Opt for stranded wire for connections to reduce stress on the buttons due to bending and twisting. A reliable practice is to use heat-shrink tubing over the connections to prevent accidental short circuits. Additionally, using a multimeter to verify continuity can help avoid potential oversights that may occur during the installation process.

For mounting, ensure that the switches are securely fastened to avoid unintentional activation. Utilize appropriate enclosures that can withstand the environmental conditions of your project, as many momentary switches are rated for specific operational limits. Furthermore, consider the placement of the switch; it should be easily accessible while minimizing the risk of accidental presses. This functionality allows for a seamless user experience, crucial for both commercial and DIY applications.

Tip: Always check the switch's specifications for voltage and current ratings, as mismatches can lead to failure or damage over time. Another tip is to conduct thorough testing after installation to ensure that each switch functions as intended within your complete system.

How to Choose the Right Momentary Push Button Switch for Your Project

| Attribute | Description | Best Practice |

|---|---|---|

| Type | Normally Open (NO) or Normally Closed (NC) | Choose based on project requirements |

| Material | Plastic or Metal | Select material based on durability needed |

| Size | Available in various sizes | Ensure it fits in your project design |

| Mounting Type | Panel mounted or PCB mounted | Choose based on assembly needs |

| Electrical Rating | Voltage and current rating | Ensure it meets your project's power requirements |

| Response Time | Time taken to activate | Select one with minimal delay, if timing is critical |

| IP Rating | Ingress Protection rating | Select according to environmental exposure |

Related Posts

-

7 Essential Tips for Choosing the Right Latching Push Button Switch

-

Exploring the Future of Smart Technology: How Illuminated Push Buttons Enhance User Experience

-

5 Best Momentary Push Button Switches for Enhanced Device Performance in 2023

-

Leading Push Button Starter Switch Manufacturers in China at the 137th Canton Fair

-

10 Essential Tips for Choosing the Perfect Push Button Starter Switch

-

2025 Market Insights: The Rise of Best Push Button Starter Switch in Global Manufacturing