How to Choose the Best Micro Switch for Your Industrial Automation Needs: A Comprehensive Guide

In the rapidly evolving landscape of industrial automation, selecting the right components is crucial for optimizing performance and reliability. Among these components, the Micro Switch plays a vital role in various applications, providing precise control and feedback to machinery and systems. This comprehensive guide explores the key factors to consider when choosing the best Micro Switch for your specific industrial automation needs.

From understanding the technical specifications to evaluating environmental conditions and compatibility with existing systems, we will cover everything you need to ensure seamless integration and functionality. As we look towards the technological trends shaping the industry in 2025 and beyond, making informed decisions about Micro Switches will not only enhance operational efficiency but also position your business for future challenges and innovations.

Understanding the Types of Micro Switches for Industrial Automation

When it comes to industrial automation, understanding the various types of micro switches is crucial for optimizing performance and reliability. Micro switches are electromechanical devices that play a pivotal role in controlling circuits. They come in various configurations, including snap-action, momentary, and latching types. Each type has distinct characteristics, making them suitable for specific applications. For instance, snap-action switches are known for their rapid response time, making them ideal for safety mechanisms, while momentary switches are commonly found in control panels.

Choosing the right micro switch involves considering factors such as load type, anticipated life cycles, and environmental conditions. Different micro switches also vary in their contact arrangements, affecting their switching capacity and overall efficacy in circuits. As industries increasingly adopt automation technologies, selecting the appropriate micro switch can lead to significant improvements in operational efficiencies and safety standards, driving innovation across applications from manufacturing to healthcare.

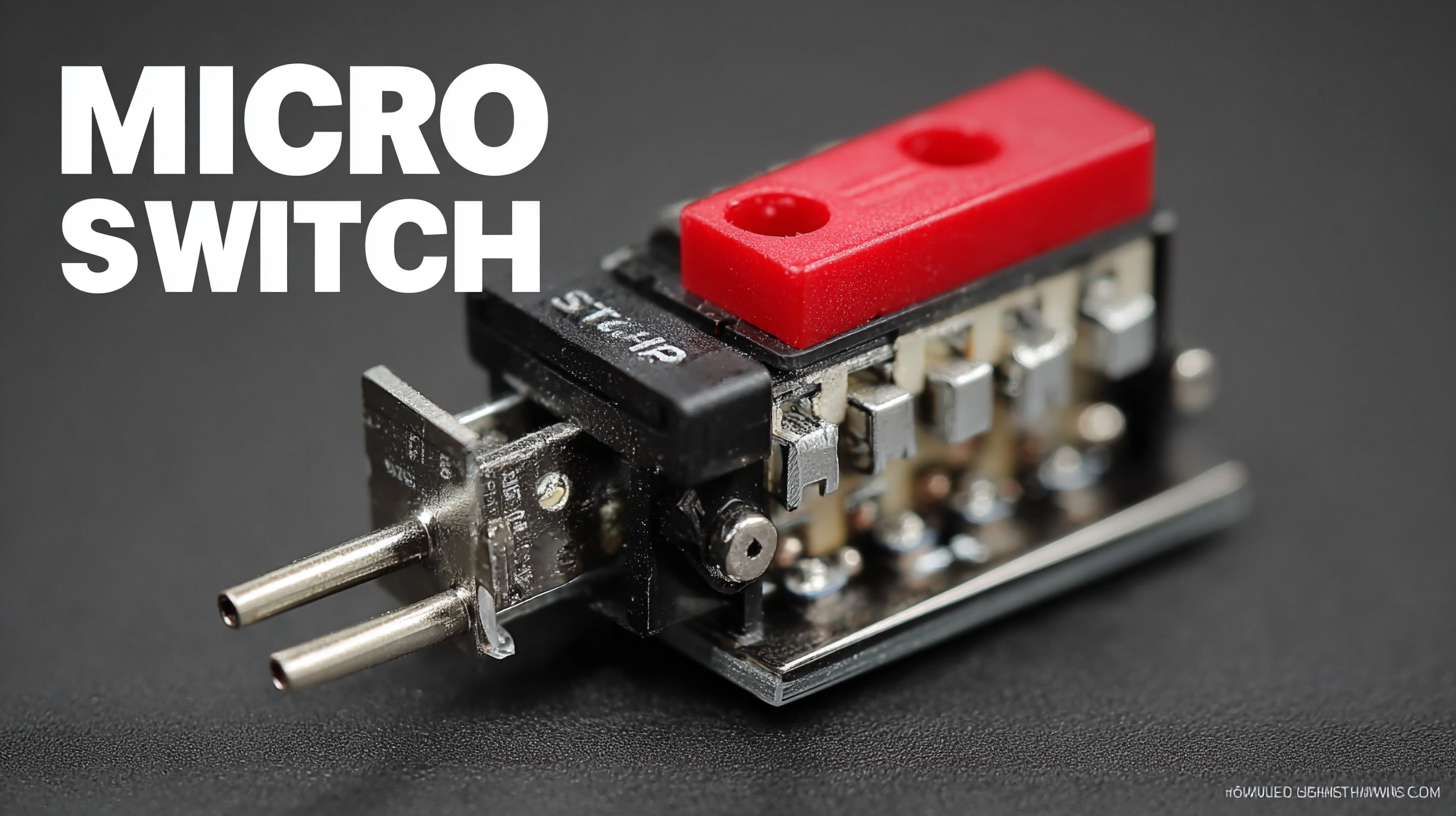

Key Factors to Consider When Selecting Micro Switches

When selecting micro switches for your industrial automation needs, several key factors come into play. First and foremost, consider the switch's operating temperature range. Micro switches can be susceptible to extreme temperatures, so ensure that the chosen switch can function effectively in your environment.

Another critical factor is the electrical specifications, including current and voltage ratings. Ensure that your selected micro switch can handle the operational loads without overheating or failing. It's also wise to evaluate the switch's mechanical life and endurance, as higher durability can lead to reduced maintenance costs and improved system reliability.

**Tips:** Always check the manufacturer's datasheet for detailed specifications to make informed decisions. Additionally, consider the design of the micro switch—its size and mounting options should align with your machine design to ensure seamless integration. Finally, think about environmental protection features, such as sealed or epoxy-coated switches, to enhance longevity in harsh conditions.

How to Choose the Best Micro Switch for Your Industrial Automation Needs: A Comprehensive Guide

| Parameter | Specifications | Considerations |

|---|---|---|

| Operating Force | 100 - 500 grams | Choose based on application pressure requirements. |

| Contact Ratings | 1A to 15A at 250VAC | Match with load current for safe operation. |

| Actuator Type | Tactile, Roller Arm, Long Stroke | Select based on space and mechanical design. |

| Environmental Conditions | IP67, Temperature range -10°C to +85°C | Ensure suitability for harsh conditions. |

| Mechanical Life | 1,000,000 operations | Consider longevity and replacement frequency. |

| Mounting Style | PCB Mount, Panel Mount | Choose based on installation space and method. |

| Cost | $0.50 - $5.00 per unit | Balance cost with features and reliability. |

Evaluating Electrical and Mechanical Specifications for Your Needs

When selecting the best micro switch for industrial automation applications, understanding both electrical and mechanical specifications is crucial. For instance, recent evaluations of materials, such as laser powder bed fused Fe-Si alloys, have demonstrated that the mechanical properties—specifically strength and ductility—are significantly enhanced compared to traditional soft magnetic composite materials. This underscores the importance of mechanical resilience in micro switches, where the choice of materials can impact durability and performance in high-stress environments.

In evaluating electrical specifications, findings from studies on cellulose-based carbon fibers reveal that the incorporation of hardwood lignin enhances not just mechanical properties, but also the electrical characteristics. This dual improvement is essential, as many industrial applications require components that can withstand mechanical strain while maintaining reliable electrical performance.

For optimal performance in automation systems, selecting micro switches that leverage innovative materials can result in higher efficiency and longevity, making thorough evaluation of both electrical and mechanical properties a key consideration.

How Environment and Application Impact Micro Switch Selection

When it comes to selecting the best micro switch for industrial automation, understanding how environmental factors and application needs impact your choice is crucial. Different environments can impose unique demands on micro switches. For instance, settings with high humidity or exposure to chemicals require switches that offer robust sealing and durability. Similarly, temperature extremes can affect the longevity and reliability of micro switches, necessitating materials and designs that can withstand such conditions.

**Tips:** Always evaluate the specific environmental conditions in which the micro switch will operate. This assessment helps you choose a switch that not only fits the technical requirements but also enhances operational reliability in challenging environments.

Additionally, consider the application type when making your selection. High-precision tasks, like those found in medical equipment, demand switches with exceptional accuracy and responsiveness. Emerging technologies, such as IoT, may require micro switches that support connectivity and smart functionalities. Thus, aligning the switch’s capabilities with your particular applications ensures optimal performance.

**Tips:** Review the application requirements carefully and check that the selected micro switch meets all necessary specifications, including electrical load and mechanical endurance. Keeping abreast of market trends and technological advancements will also aid in making informed decisions.

Best Practices for Installation and Maintenance of Micro Switches

When it comes to the installation and maintenance of micro switches in industrial automation, adhering to best practices is crucial for ensuring optimal performance and longevity. A report from the International Electrotechnical Commission (IEC) indicates that improper installation can lead to a failure rate of up to 30% in industrial environments. To mitigate these risks, it is essential to carefully assess the mechanical and electrical specifications of the micro switch before installation, ensuring compatibility with the intended application.

In addition to careful placement, regular maintenance is key to prolonging the life of micro switches. The Machinery Directive (2006/42/EC) emphasizes the importance of periodic inspections, recommending maintenance intervals based on usage frequency and environmental factors. For instance, environments with high dust or moisture levels may require more frequent checks of switch actuators and connectors to prevent malfunctions. Furthermore, conducting tests for electrical continuity and contact wear can preempt potential failures, ensuring that the micro switches perform reliably in critical automation tasks.